03. Under the condition that the grade of the dry tailings is equal to or even lower than that of conventional magnetic roller or conventional dry separator, for highgrade and rich magnetite with different features, by adjusting corresponding technical parameters and structure, about 10%30% tailings discharging and about %% of concentration grade can be increased compared to ...

احصل على السعر

04/10/2018 · Magnetic Separation and Iron Ore Beneficiation. Magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron. Since 1849, a number of patents on magnetic separation have been issued in USA, and texts of some of the patents before 1910 describe a variety of magnetic separators for mineral processing.

احصل على السعر

For mining industry, the magnetic separator is suitable for wet or dry magnetic separation of manganese ore, magnetite, pyrrhotite, roasted ore, ilmenite, hematite limonite and other materials with particle size less than 23mm. It is also used for iron removal of coal, nonmetallic ore, building materials and other materials.

احصل على السعر

SLon Magnetic Separator Ltd. SLon is owned by Jiangxi Tungsten Holding Group Company Limited, and its research on magnetic separation equipment began in 1985. SLon is the inventor of WHIMS. It has won the second prize of National Science and Technology Progress award, National Technological Invention Award. Besides, it owns 15 invention patents ...

احصل على السعر

This type of magnetic separation machine is used in wet separation processes for smaller than 1,2 mm ( – 200 mesh of 30100 %) of fine grained red mine (hematite) limonite, manganese ore, ilmenite and some kinds of weakly magnetic minerals like quartz, feldspar, nepheline ore and kaolin in order to remove impurity iron and to purify them.

احصل على السعر

Dry Magnetic Separation of Iron Ore: There are many inherent advantages in processes that utilize dry magnetic separation to beneficiate iron ore. Wet concentration of magnetite ore, in comparison, re quires 500 to 1000 gal of water per ton of concen trate produced. This means extensive use of water resources, as well as disposal systems and some times complied water reclamation systems ...

احصل على السعر

Slurry Pumps. Demagnetising Coil. Dry drum magnetic separators. Heavy Media Drum Separators. Multotec successfully delivers two overbelt magnets. Overbelt Magnetic Separators. Permax Wet Drum Magnetic Separators. Pulping Chute. Wet high intensity magnetic separators.

احصل على السعر

16/07/2020 · Vale has inaugurated its new dry pilot plant for processing iron ore in Minas Gerais, Brazil, as it continues to reduce its use of water in ore and waste processing. The Brazilian technology, known as FDMS (Fines Dry Magnetic Separation), is unique and has been developed by New Steel – a company Vale acquired in late 2018.

احصل على السعر

Dry magnetic separation of iron ore of the Bakchar deposit Ezhov a *, Y ... As follows from Fig. 3 separation of the magnetic concentrate begins after the amperage equal to 2A, because before that the value of the magnetic force is not enough to separate magnetic and diamagnetic particles. After 3A the concentrate yield rises sharply, but after 6A this tendency is slowing down and, after ...

احصل على السعر

Magnetic Separation. Multotec supplies a complete range of magnetic separation equipment for separating ferromagnetic and paramagnetic particles from dry solids or slurries, or for removing tramp metal. Multotec Dry and Wet Drum Separators, WHIMS, Demagnetising Coils and Overbelt Magnets are used in mineral processing plants across the world.

احصل على السعر

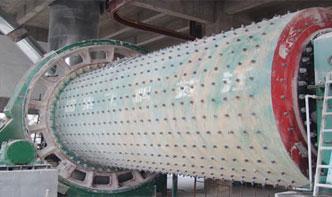

Wet Drum Magnetic Separator is a widely used magnetic separator for iron ore beneficiation. Lots of iron ore plant will in stallate a batch of WLIMS to concentrate the low grade iron ore. Permanent Overband Magnet . Permanent Overband Magnets are designed with a continuously running belt to tramp and automatically remove ferrous metal from conveyed material. Block Magnet . The manual cleaning ...

احصل على السعر

silica sands and a variety of other industrial minerals. Wet, high intensity magnetic separators (WHIMS) generate high field strengths and pass slurry through matrix arrangements to collect the magnetic fraction. WHIMS are traditionally applied in mineral sands to collect ilmenite in the early stages of a flowsheet, and have a host of other common uses including iron ore (haematite ...

احصل على السعر

01/01/2015 · On the other hand, the magnetic products from the LIMS and SLon magnetic separators are fed to the secondary ball mill system, ground to about 80% 75 μm, and finally treated by drum LIMS and SLon magnetic separators for cleaning and scavenging to recover about 30% of the mass as the final iron ore concentrate, with about 15% of the mass discharged as the final tails. Because the .

احصل على السعر

Abstract. Dry high intensity magnetic separation (DHIMS) is investigated to process a lean hematite ore. It was found the feed particle size and the drum rotation speed have significant influences ...

احصل على السعر

concentration and wet or dry magnetic separation equipment to separate more strongly susceptible material from low (or minimal) susceptibility material. Various types of jigs can also be used for the coarser fractions. The mineralogy and liberation characteristics of the ore significantly influence the subsequent flow sheet. A review of iron ore processing practices has been published by O ...

احصل على السعر

15/05/2019 · In this research, the efficiency of magnetic separation methods for processing of a lowgrade iron pigments ore (red ochre) has been studied. Based on the mineralogical analyses (XRD), thin section and polish studies, the reserve is an iron sedimentary deposit with an average Fe grade of % The most valuable minerals are Hematite and Goethite and main gangue minerals are Calcite .

احصل على السعر

The Appliion of New SLon Magnetic Separation Technology in Ilmenite Processing. Apr, 30. 2021 | 37 View. SLon Magnetic Separator Limited is the inventor and promoter of Wet High Intensity Magnetic Separator (WHIMS). In the past 30 years, the technical team led by Dr. XiongDahe has always taken the development of magnetoelectricity mineral ...

احصل على السعر

Magnetic separator is widely used in different kind mineral processing, including metallic minerals such as iron ore, chrome ore, ilmenite, and nonmetallic minerals for iron removing such as quartz processing, kaolin processing, etc. Prominer supplies various types of magnetic separators for different appliions, including dry drum magnetic separator, wet drum magnetic separator, LIMS, HIMS ...

احصل على السعر

2 Description of industrial magnetic separation process The Golgohar ore body is loed in southeast Iran, which contains half billion tons of ore having about 42% iron. Golgohar Mining and Industrial Company operates six separated ore bodies of Golgohar. It produces million tons of iron ore concentrate, 157 thousand tons of ne iron ore ...

احصل على السعر

11/01/2019 · Highintensity wet magnetic, lowintensity dry magnetic and falcon gravity separators were applied to the roasted and unroasted ores at the optimum test conditions. After conversion, the iron concentrations in the grade that could be sold (>56% Fe) were obtained by the wet magnetic separator and the falcon gravity separator with the recovery yields of and %, respectively. The ...

احصل على السعر

Use ore sorting equipment to concentrate ores and cut process costs There are many ways of improving recovery processes for a wide variety of ores using sorting equipment. At STEINERT we always take the same approach: sorting waste rock and ore with low concentrations out from the process at an early stage to save energy and resources and to unlock more enriched ore more effectively.

احصل على السعر

has been used to process and commercially separate a wide range of industrial minerals and other dry granular powders. Here, benchscale results are presented on the beneficiation of lowgrade Fe ore fines using STET belt separation process. Benchscale testing demonstrated the capability of the STET technology to simultaneously recover Fe and reject 5 E 1 6 from itabirite ore with a D50 of ...

احصل على السعر

01/01/2013 · Processes involving combination of classifiion, dry magnetic separation and wet magnetic separation were carried out to upgrade the low grade siliceous iron ore sample to make it suitable as a marketable product. The sample was first ground and each closed size sieve fractions were subjected to dry magnetic separation and it was observed that limited upgradation is possible. The .

احصل على السعر

Magnetic Separator Working Video. Introduction of Magnetic Separator: Magnetic separator is the professional refinement and iron removal equipment that can be used in the magnetic iron ore the dressing process such as magnetite, hematite, magnetic pyrite and limonite and nonmetallic materials iron removal working including coal, quartz and gypsum.. The magnetic system of high intensity wet ...

احصل على السعر

Dry magnetic concentration. Another solution that has been studied is the dry magnetic concentration of iron ore based on the technology developed by New Steel, a company acquired by Vale at the end of 2018. This technology eliminates the use of water in the process of concentrating the low iron content ore, which allows the tailings to be disposed of in piles as waste rock, similar to the ...

احصل على السعر