Most of mining companies are following advice from crusher manufacturer, to take preventive maintenance, which can be a regular fleet. Such as every 8hrs, 40hrs, 200hrs, 2000hrs, etc. Site operators will replace the worn parts or equipment during these periods to avoid major failures or unplanned downtime.

احصل على السعر

· Often, the crusher is built below or on top of an ore pass, which brings up practical and safety issues in installation and also in maintenance. Safe .

احصل على السعر

Mine Crusher Maintenance; Mine Crusher Maintenance. Nov 28 2018nbsp018332Crushers are used in the mining industry construction and other sectors to break large rocks down into smaller more manageable pieces There is a wide range of crushers available that employ different physical methods to achieve this goal Follow crusher backing maintenance schedule carefully to avoid undue damage .

احصل على السعر

Job Summary Crusher Mechanic. Provide preventive and corrective maintenance to Crusher and associated equipment in support of mining operations Responsibilities. Promote a safe work environment for yourself, other employees and contractor personnel

احصل على السعر

MBMMLLC: Jaw crusher maintenance and operation video. 1 Apr 2015 MBMMLLC: Jaw crusher maintenance and operation video If you have purchased one of our jaw crushers and have any questions after Intro to MBMM and Shop Tour, Mining, Recycling, and Crushing Equipment . get price. Jaw Crushers for Sale or Rent Jaw Crusher Parts, Service. Powerscreen jaw crushers are designed .

احصل على السعر

pattern of crushing plant of complex mining equipment. • To estimate the reliability and maintainability characteristics of crushing plant in absolute quantitative terms. • To identify the critical subsystems which require further improvement through effective maintenance policies to enhance the operational reliability of mining operation,

احصل على السعر

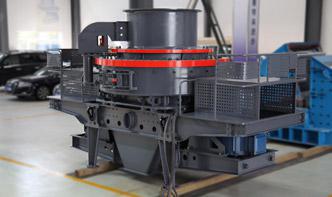

· · 4 Types of Stone Crushers' Maintenance and Efficient Improvement. There are different types of stone crushers in mining industry such as jaw crusher, cone crusher, impact crusher, and sand making machine. This article will tell you how to maintain the 4 types of rock crushers and how to efficicently improve their performance. Many stone crusher ...

احصل على السعر

Mine Crusher Maintenance Procedures. Jaw crusher maintenance Pit Quarry Feb 01 2014 183 Successful jaw crusher maintenance requires the right resources the right tools and the right approach says Bill Macini a service technician Certainly when an operation is down whether for preventive maintenance or component failure there is always the pressure to get the plant up and running as ...

احصل على السعر

25/08/2021 · Mobile crushers can remain dependable throughout their working life when proper maintenance practices are followed. Crushing and processing material can result in excessive wear on certain components, excessive vibration throughout a plant, and .

احصل على السعر

449 Int. J. Mech. Eng. Rob. Res. 2013 Girja Lodhi, 2013 OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL HANDLING IN THERMAL POWER PLANT Girja Lodhi1* *Corresponding Author: Girja Lodhi, Many utility systems in the world have power plants operating with fossil fuel.

احصل على السعر

How To Do Maintenance and Repair of Jaw Crusher? Jaw crusher is a universal stone crusher in the mining industry. Appliion: jaw crusher machine widely used in the mineral processing plant, building material industry, aggregate processing plant, roads, railways, water conservancy, chemical and so .

احصل على السعر

· 4 Types of Stone Crushers' Maintenance and Efficient Improvement. There are different types of stone crushers in mining industry such as jaw crusher, cone crusher, impact crusher, and sand making machine. This article will tell you how to maintain the 4 types of rock crushers and how to efficicently improve their performance. Many stone crusher ...

احصل على السعر

Mine Crusher Maintenance. 3 Construction Working and Maintenance of Crushers for Crushing Bulk Materials Crushers for Bulk Materials Crushers and breakers are used to reduce size of mined and quarried material for further processing or to size suitable for the intended end use The goal of a crusher is to crush the. Send Email: [email protected] Get Price List Chat ...

احصل على السعر

You need your crushers to be as efficient and economical as possible for the optimal production output of your mine. With the precise speed and torque provided by our low and medium voltage AC drives, the mechanical stress on the crusher and the motor is vastly reduced from .

احصل على السعر

· To demonstrate how wellmaintained crushers can improve the overall efficiency of the comminution process, Erlynne uses an example from Westgold Resources' Bluebird mine site in .

احصل على السعر

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a doubletoggle Jaw Crusher. Introduced in 1906, McLanahan's Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers. On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavyduty double ...

احصل على السعر

Quarry, mine and mobile plant maintenance are NCCM's core business. We provide aspects of maintenance to hard rock and sand quarries, recycling plants, mobile crushing plants, landfill operations, concrete and asphalt plants, depots and workshops. Our aim is to ensure our service is not only efficient and reliable but a fully comprehensive ...

احصل على السعر

crushers sink crushers jaw crushers 1036 used small gold minning rock crushers all crushers manufacturer in tamill nadu business profile for maintenance of mine crushers about crushers and prices how cone crushers work small stationary crushers for sale sand stone crushers how do i calculate blow bar wear life in impact crushers.

احصل على السعر

Mine Crusher Maintenance. FOB Reference Price: Get Latest Price Coal crusher maintenance manual sandpalmdoorscoza. coal crusher machine manual Machinery is one of the biggest manufacturers in Development Of Condition Based Maintenance For Coal Get Price operation and maintenance of crusher house for coal handling ijmerr The failures of these equipments have led to high .

احصل على السعر

Crushers play an important role in the material handling process for underground mine operations. The main purpose of a crusher is the size reduction of the feed. This size reduction is achieved by applying a force to the material, creating cracks in the material which in the end will cause the material to break into smaller pieces. There are ...

احصل على السعر

Planning tools for mining maintenance A truly industryleading maintenance strategy is comprehensive. It focuses on your specific priorities, bringing together safety, planning, documentation, inventory, staffing and reporting requirements.

احصل على السعر

01/08/2019 · In the mining industry, the most common crusher types are jaw crusher and cone crusher. Jaw crusher is usually used for primary crushing, and cone crusher is used for secondary crushing. The material of crusher plays an important role in its working efficiency and service life. However, the regular operation and maintenance are important, too.

احصل على السعر

08/08/2017 · Regular crusher maintenance integral to reliability, performance and output. Crushers operate at high power, force and capacity in order to produce the required materials. Minerals told IM: "This puts a great deal of strain on the crusher and its wear parts, which operators must be aware of when carrying out maintenance.

احصل على السعر

Mine haultruck capacity is an important factor at primary crusher installations, because it is costeffective to integrate truck cycle time at the crusher station with mine/shovel operations. If a primary crusher dump pocket is undersized and unable to handle the mine's trucks, then operators must slowly meter the ore into the receiving hopper.

احصل على السعر

ANALYSIS OF FAILURE STATISTICS FOR CONE CRUSHER MAINTENANCE VisaVis OPERATIONAL RELIABILITY ASSESSMENT R. S. SINHA 1 A. K. MUKHOPADHYAY 2 1Research Scholar, Department of Mechanical Engineering and Mining Machinery Engineering, Indian School of Mines, Dhanbad, Jharkhand, India 2Professor, Department of Mechanical Engineering and Mining .

احصل على السعر