Care and Maintenance of Bearings (Revised) We thank you for your interest in NTN bearings. This booklet is intended as a guide to bearing maintenance, with the main consideration being onsite bearing maintenance. Bearings may fail earlier than the expected rolling fatigue life. Early failure is mostly attributable to inadequate handling or ...

احصل على السعر

Special maintenance method for ball mill large girth gear Editor The most used equipment in the metallurgical industry building materials industry chemical industry etc is the rotary kiln and the key component in the rotary kiln transmission is the large girth gear which is connected by a pair of screws used by the two half .

احصل على السعر

Welcome to another MachMotion minute, let's make your day a little more automated! In this article we will talk about when to use hardware or software to correct backlash. We will also take a closer look at why speeds, temperatures and vibration can cause backlash issues.

احصل على السعر

· Keep the air in your shop dry. Controlling the internal conditions of a machine shop is the first thing you should do to prevent rust from forming on tools and machines. Since rust is related to humidity, the goal is to keep the air as dry as possible. The best way to control humidity and temperature is by installing an air conditioning system.

احصل على السعر

Ball mills normally operate with an approximate ball charge of 30%. Ball mills are characterized by their smaller (comparatively) diameter and longer length, and often have a length to times the diameter.

احصل على السعر

· Ball cutters, also known as ball mills, have a hemispherical cutting tip. The objective is to maintain a corner radius for perpendicular faces. Slab mill. Slab mills are not that common with modern machining centres. Rather, they are still used with manual milling .

احصل على السعر

Industrial Ball Mills can operate constantly, fed at one finish and discharged at the other to mediumsized ball mills are mechanically rotated on their axis, but small ones usually consist of a cylindrical capped container that sits on two drive shafts (pulleys and belts are used to transmit rotary movement).A rock tumbler capabilities on the same principle.

احصل على السعر

Total Guide to CNC Jigs, Fixtures, and Workholding Solutions for Mills. Workholding is the generic term for any device used to firmly hold your workpiece while machining it. Closely related terms are "jigs" and "fixtures.". A fixture holds your workpiece while it is being cut. .

احصل على السعر

Scheduled offline maintenance or failure of one of the Ball Mills (or its ancillary equipment) causes a 50% loss of milling production. Most of the maintenance results from timedependent failure mechanisms ( wear, corrosion or fouling). The crushing circuit has a .

احصل على السعر

A ball mill with simple structure. Production capacity: ~170t/h. Product Improvement: Wet type overflow ball mill is lined with Xinhai wearresistant rubber sheet with excellent wear resistance, long service life and convenient maintenance..

احصل على السعر

· Ball Mill Maintenance when using ball mill. This post is about how to maintenance ball mill. PR

احصل على السعر

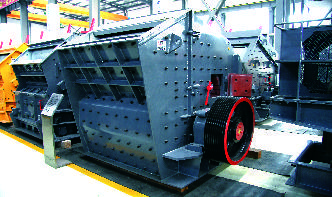

Ball Mills 【Capacity】 T/H 【Advantages】Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of processing capacity 【Max Feeding Size】 <25mm 【Discharge Size】 【Types】Overflow ball mills, grate discharge ball mills 【Service】 24hrs quotation, custommade parts, processing .

احصل على السعر

the right type of mill, how to operate your mill efficiently, and how to maintain your mill. There are numerous types of grinding mills. This article focuses on two widely used types: the hammer mill and the jet mill. Hammer mills are often used for generalpurpose .

احصل على السعر

The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance. With more than 4000 references worldwide, the FL ball mill is proven to do just that. What we offer. The ultimate ball mill – with flexibility built in. You can't optimise cement grinding with a ...

احصل على السعر

· Ball Mill Maintenance and Repair Method XinHai Views (321) Warm Tip: If you want to know the product price, particle size, production capacity, size, etc., please Click here, and contact us online. Ball mill is the largest consumption equipment of mining plant. The ball mills operating state ...

احصل على السعر

· to how maintenance can be performed to ensure equipment reaches or exceeds its design life have been developed in the United States. In addition to waiting for a piece of equipment to fail (reactive maintenance), we can utilize preventive maintenance, predictive maintenance, or reliability centered . maintenance. Reactive Maintenance

احصل على السعر